Views: 0 Author: Site Editor Publish Time: 2025-02-27 Origin: Site

Encoders play a crucial role in a variety of industrial and technological systems by converting mechanical motion into electrical signals. They help in determining the position, speed, and direction of a rotating object, whether it's in a robotic arm, a CNC machine, or a conveyor system. However, not all encoders are created equal, and understanding the difference between single-turn encoders and multi-turn encoders is vital to selecting the right one for a specific application. This article will explore the key differences, working principles, applications, and important considerations when selecting between single-turn encoders and multi-turn encoders.

Before diving into the differences, it's important to first grasp the concept of an encoder. An encoder is a device that provides feedback about the position, velocity, or direction of a rotating object. There are different types of encoders, with absolute encoders and incremental encoders being the most common. These devices find applications in numerous industries, including robotics, automation, aerospace, and automotive, to name a few.

In terms of mechanical motion, encoders are typically categorized based on the number of turns they are capable of measuring. This brings us to the single-turn encoder and multi-turn encoder.

A single-turn encoder is a type of encoder that measures the position of a rotating object within a single revolution. This means it can detect the movement from 0 to 360 degrees, but it does not track the number of full rotations beyond that. When the encoder completes a full turn, it resets to its original position.

Single-turn encoders are commonly used in systems where a full rotation is enough to measure the position of the object, and the system doesn’t require additional turn tracking. These types of encoders are often found in applications such as:

Robotic arms: Where tracking the position within one revolution is sufficient.

Linear motion systems: To track movement along a fixed path.

CNC machines: When one rotation is enough to control the position of the machine components.

Single-turn encoders are typically used for applications requiring high resolution, meaning they can measure position with very fine granularity within the single revolution.

A multi-turn encoder, on the other hand, is capable of measuring not just the position within a single revolution, but also the number of revolutions, providing an accurate count of multiple turns. These encoders can track both the absolute position of the shaft as well as the total number of rotations made, which is ideal for more complex applications where precise multi-turn information is essential.

Multi-turn encoders often use an additional internal mechanism or counter to track the number of turns, making them more suitable for applications requiring continuous rotation measurement.

Applications of multi-turn encoders include:

Automated machinery: Where the system needs to know how many full rotations the motor has made.

Elevator systems: Tracking the position of an elevator over multiple floors.

Wind turbines: To measure the blade rotations over time.

High-precision automation: Applications requiring continuous feedback over multiple rotations.

Measurement Range:

A single-turn encoder measures within a single revolution, up to 360 degrees.

A multi-turn encoder tracks multiple rotations, providing absolute position data over several turns.

Complexity:

Single-turn encoders are simpler, measuring just one revolution. Their output is typically easier to interpret and requires less data processing.

Multi-turn encoders are more complex, as they track multiple revolutions and require additional mechanisms or counters to store the rotational data.

Applications:

Single-turn encoders are used when a device needs to know its position within one turn of the shaft.

Multi-turn encoders are ideal for applications requiring feedback on multiple turns or more complex rotational data.

Resolution:

Encoder resolution refers to the smallest measurable increment in the rotation of the encoder shaft. Single-turn encoders often have higher resolution within their single revolution range compared to multi-turn encoders.

For high-precision applications, such as robotics or precision machinery, the encoder resolution plays a crucial role in ensuring accuracy. Single-turn encoders generally provide better encoder resolution for small, precise movements within one turn.

Power Consumption:

Multi-turn encoders often consume more power due to the additional mechanism required to track multiple turns.

Single-turn encoders generally consume less power because they only need to track one revolution.

Size and Cost:

Single-turn encoders are typically smaller and less expensive compared to multi-turn encoders, which are often bulkier and more costly due to their added complexity.

Understanding where each type of encoder fits best in real-world scenarios helps in making an informed decision about which one to choose for a particular application.

Industrial Robots: Robots often use single-turn encoders to track the position of a joint or arm, allowing precise control within one revolution.

CNC Machines: Single-turn encoders provide the necessary feedback for machine positioning, ensuring that the equipment operates within the specified tolerances.

Automation Systems: In applications like conveyor systems, single-turn encoders help track linear movement without the need to track multiple rotations.

Aerospace: In satellite or spacecraft positioning systems, single-turn encoders are used for precise position feedback within a single turn of the motor.

Wind Turbines: Multi-turn encoders track the rotation of turbine blades over several turns, providing valuable data for performance monitoring and control.

Elevator Systems: Multi-turn encoders track the position of the elevator over multiple floors, ensuring the lift operates smoothly.

Automated Storage Systems: In systems that rotate or lift items, multi-turn encoders provide feedback on multiple rotations of the moving parts.

Precision Manufacturing: In high-precision equipment that involves continuous rotational movement, multi-turn encoders provide accurate tracking of multiple turns.

Q1: What is the primary difference between single-turn and multi-turn encoders?

A1: The primary difference is that single-turn encoders track position within one full revolution (360 degrees), while multi-turn encoders can track multiple rotations, providing absolute position feedback over several turns.

Q2: Which type of encoder is better for industrial applications?

A2: It depends on the application. If the position within a single rotation is sufficient, a single-turn encoder is ideal. For applications requiring continuous feedback over multiple turns, such as automated machinery or elevator systems, a multi-turn encoder would be more appropriate.

Q3: What does encoder resolution mean?

A3: Encoder resolution refers to the smallest measurable increment of rotation that an encoder can detect. Higher resolution results in more precise measurements of position. Single-turn encoders typically offer higher resolution for detailed movements within one turn.

Q4: Can a single-turn encoder be used in place of a multi-turn encoder?

A4: In some cases, single-turn encoders can be used for simpler applications where only position within one revolution matters. However, for applications that need continuous feedback over multiple rotations, a multi-turn encoder is necessary.

Understanding the differences between single-turn encoders and multi-turn encoders is essential when selecting the right encoder for your needs. Single-turn encoders are best suited for applications that only require position feedback within one rotation, while multi-turn encoders are ideal for applications where multiple rotations need to be tracked. Additionally, factors such as encoder resolution, application complexity, power consumption, and cost should all be considered when making a decision.

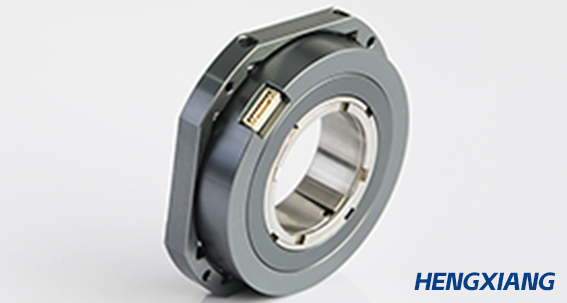

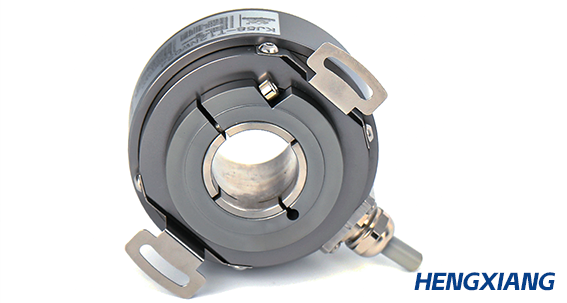

At Shanghai Hengxiang Optical Electronics Co., Ltd., we offer a wide range of encoders, including both single-turn encoders and multi-turn encoders, to meet your specific application needs. Our products are designed with the latest technology, ensuring superior performance, accuracy, and reliability.

Quality Assurance: All our products meet international certifications such as CE-ATC, ISO, and QMS standards.

Leading Technology: We leverage advanced sensor technology and innovative design to offer highly accurate and reliable encoders.

Tailor-Made Solutions: We provide customized encoder solutions based on your precise requirements.

Efficient Service: From design and production to shipping and distribution, we offer a seamless one-stop service.