Views: 0 Author: Site Editor Publish Time: 2025-07-17 Origin: Site

Sub-divisional error in linear encoders is a repeating mistake. It happens when problems change the sine and cosine signals from the encoder's read head. This error shows up again and again with each signal period. It does not get worse as you move farther. Sub-divisional error stays very small, in the nanometer range. Even tiny changes are important. Manufacturers put sub-divisional error values in datasheets. This helps you see how much it could change your accuracy. You need low sub-divisional error for good precision in tough jobs.

Sub-divisional error is a small mistake that repeats in linear encoders. It affects how accurate the measurement is, but it does not get worse as you measure farther. Clean and balanced sine and cosine signals are very important. They help lower sub-divisional error and make your system more exact. Installing things the right way is important too. You need to line things up carefully, control the temperature, and stop vibrations. This helps make sub-divisional error much smaller. Some encoders have electronic fixes and special mechanical parts. These can correct signal mistakes and give more detailed measurements. You should test often with tools like Lissajous patterns. Calibrating a lot also keeps sub-divisional error low and makes sure your system works well.

Linear encoders are like rulers that use light to measure. They have a scale with a pattern that repeats. The reading head shines light on the scale. It looks at the light that comes back or goes through. This makes two signals called sine and cosine waves. These waves are in quadrature, so they are 90 degrees apart. The reading head checks signals from a big area. This helps cut down noise and keeps signals steady. Dust or heat changes do not mess up the signals much.

Most linear encoders use optical ways to work. They use diffraction gratings to split light into parts. The ±1 order light makes clean sine and cosine signals. These signals show the exact spot. The ±2 order light helps find motion mistakes, like pitch or yaw. Some encoders use Moiré patterns or other tricks with light. These ways help keep signals clean. Cleaner signals mean less interpolation error and better detail.

The analog sine and cosine signals are not digital yet. The encoder must split each signal period into tiny steps. This is called interpolation. It lets you get much more detail than the scale lines.

Interpolation checks the shape of the sine and cosine waves. If signals are perfect, interpolation error is very small. But real signals can have problems. The size can change, the phase can shift, or the shape can be wrong. These problems make interpolation error. The error repeats every signal period. It limits the best detail you can trust.

Interpolation error can get worse when you go faster. This happens because the signals change shape at high speed. The second harmonic in the signal often causes most of the error. Shaking or changes in the light path can make it worse. You can try to fix these errors, but it is hard. The best way is to have clean signals and good design.

Tip: Always look at the encoder's datasheet for interpolation error and detail. Lower error and higher detail mean better results for your job.

Sub-divisional error can come from many places inside a linear encoder. You need to know these causes to keep your system working well. Sub-divisional error is one of three main errors in linear encoder accuracy. The other two are slope error and linearity error. Each cause can change how much you trust the position and speed readings.

Signal imperfections are the biggest reason for sub-divisional error. These problems happen when the sine and cosine signals do not look right. The signals might have:

Offset (the wave's center moves up or down)

Imbalance (one wave is bigger than the other)

Phase error (the waves are not 90 degrees apart)

Harmonic distortion (the waves are not smooth)

These problems make the signals non-linear. When you split the signal into small steps, the errors repeat every period. This repeating pattern is called sub-divisional error. Even if the signal is strong, phase errors and distortion can still hurt accuracy. Some encoders use special chips or software to fix offset and imbalance. You usually fix phase error during setup. If you want the best accuracy, you must keep these signal problems very small.

Note: Bad signals cause repeating errors that limit how closely you can measure position. Always check for clean, balanced signals when setting up.

Problems with the scale and how you put it in place also cause sub-divisional error. The scale has tiny lines or patterns. If these lines are not perfect, you get errors. Common problems include:

Varying duty cycle (the line width changes)

Scale bends during mounting

The scale grows or shrinks from temperature

The scale bends from different temperatures

Different materials in the encoder grow at different rates

These problems change the space between the lines. When the space changes, the signals from the read head do not match the real position. Temperature can stretch or shrink the scale, making the error worse. You cannot always fix these errors with signal correction. You need to mount the scale carefully and control the temperature for the best results.

Here is a quick list of main causes from recent studies:

High frequency sub-divisional error repeats at each scale period.

Mistakes in making the grating.

Scale bends from mounting.

Temperature changes and differences.

Mechanical shaking and bumps.

The reading head and its optics are also important for sub-divisional error. The optics must see the scale pattern clearly. If the optics have problems, you get errors. Problems can come from:

Dust or scratches on the optics

The head and scale are not lined up

The reading head tilts or turns

Bad optical design

If the head tilts or moves, the light path changes. This change makes the signals worse and increases sub-divisional error. Shaking or bumps can also move the head, causing random errors. Good design and careful setup help keep the optics clean and lined up. Some encoders use special coatings or covers to protect the optics.

Error Component | Description | Key Characteristics |

|---|---|---|

Slope Error | Biggest error that adds up, can be fixed by the controller | Adds up over travel; affects total accuracy |

Linearity Error | Range of error that does not add up after slope error is fixed | Measured in micrometers per meter; does not add up |

Sub-divisional Error | Repeating error every scale period, caused by signal and mechanical problems | Limits how close you can measure; does not add up |

You must watch for all these causes if you want your linear encoder to be as accurate as possible. Sub-divisional error can limit your system, even if other errors are small. By knowing these causes, you can try to make them smaller and get better results.

You can check sub-divisional error by watching the sine and cosine signals. These signals come from the read head as it moves on the scale. To find errors, you draw one signal on the X-axis and the other on the Y-axis. This makes a shape called a Lissajous pattern. If the signals are perfect, the pattern is a circle at the center. This means there is no sub-divisional error. If the circle looks squished, moved, or twisted, something is wrong. Problems like amplitude mismatch, phase shift, or offset change the pattern. You can spot these problems fast, so this method helps you fix errors quickly.

Tip: Lissajous patterns help you find signal problems before they mess up your measurements.

Scientists and engineers use this method in labs and factories. They also use harmonic analysis to look for extra waves in the signal. Third-order harmonics often show up when the scale or optics have problems. By looking at these patterns, you can learn about and lower sub-divisional error.

You need to know how big the sub-divisional error is. Most people use nanometers (nm) to show the size of this error in linear encoders. For rotary encoders, they use degrees. In the best encoders, the error is about 1 to 2 percent of the signal period. This small number is very important for high-precision work.

Sub-divisional error repeats every signal period.

The error size limits the smallest step you can trust.

Big errors make it hard to get the same results every time.

Here is a table of important standards and sources for measuring and lowering sub-divisional error:

Source/Standard/Technique | Description | Time Period | Measurement Uncertainty or Improvement |

|---|---|---|---|

NIST Internal Reports (NISTIR 4757, NISTIR 5615 by D. Swyt) | Talk about problems with tight tolerances and assemblies for SDE measurement and reduction | Contemporary | Key references for SDE in precision engineering |

ISO Standard for Reference Temperature (ISO, 1975) | Gives standard conditions for size measurements | Since 1975 | Basis for steady measurement conditions |

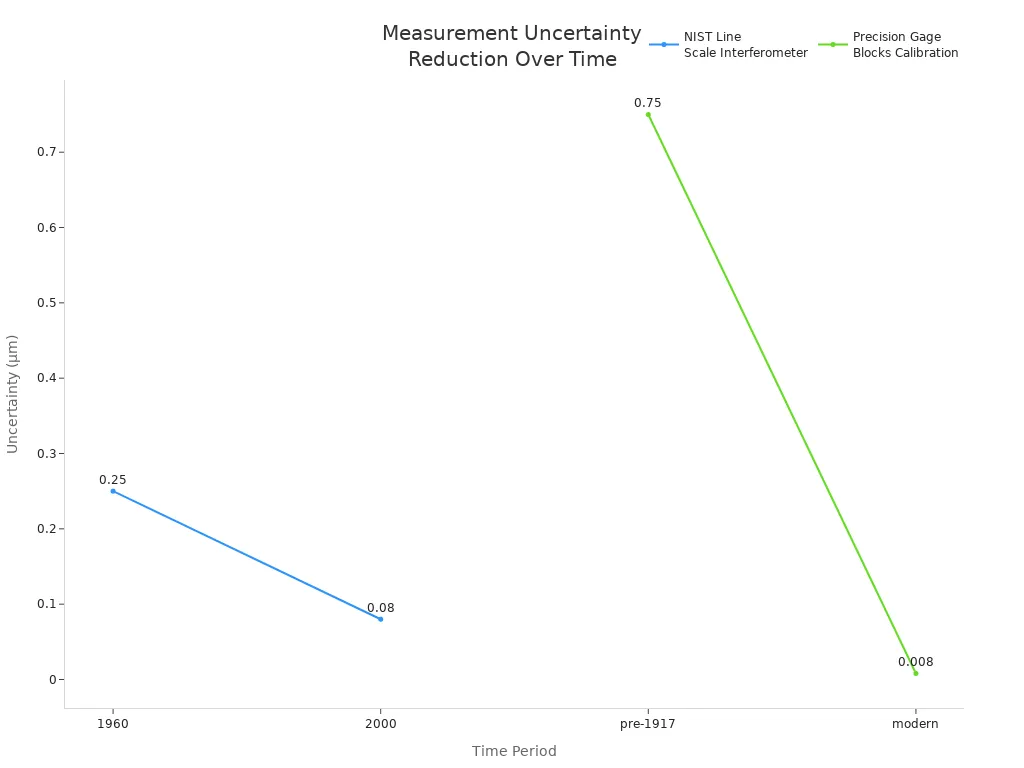

NIST Line Scale Interferometer System | Interferometric system for length standards | Started 1965, used after 1971 too | Uncertainty dropped from 0.25 μm (1960) to 0.08 μm (2000) at 1 m scale |

Precision Gage Blocks Calibration by NBS/NIST | Used mechanical-contact comparators first, then interferometric ways | 1901 to now | Uncertainty got better from 0.75 μm (before 1917) to 0.008 μm (now) at 1 mm scale |

The chart shows that measurement uncertainty has gone down a lot over time. This progress helps you get better results from your encoders. When you measure and control sub-divisional error, you make sure your system gives you the best accuracy.

Sub-divisional error can make it hard to control position. This is a big problem in jobs that need high precision, like CNC machines or robots. When the encoder's signals have small mistakes, errors show up again and again in each signal period. These errors do not add up over long moves, but they still affect your results.

You want high resolution to see very small changes in position. Sub-divisional error makes it tough to trust the tiniest steps. If you use a direct drive system, you need the best accuracy. Even a tiny error can make the machine stop in the wrong place. This can cause bad parts or waste time.

Here are some things you might notice:

The machine stops a bit too soon or too late.

The control system cannot keep the exact spot.

The measured position jumps by a few nanometers.

Tip: Always look at the encoder's datasheet for sub-divisional error. Lower numbers mean better accuracy and higher resolution.

Sub-divisional error does not only affect position. It also changes how smooth your machine moves. When you use the encoder to check speed, the control system watches how fast the position changes. If the position jumps, the speed reading jumps too. This is called velocity ripple.

You might hear or feel this as buzzing or shaking. The motor may use more power and get hot. At higher speeds, these ripples happen more often. The control system may not react fast enough, so the machine can shake or make noise.

Here is a table that shows what you might see:

Effect | What You Notice | Why It Happens |

|---|---|---|

Position error | Stops in the wrong place | Sub-divisional error in signals |

Velocity ripple | Buzzing or vibration | Speed reading jumps |

Higher motor current | Motor gets hot | Control system works harder |

You can make these problems smaller by choosing encoders with low sub-divisional error. This helps you get better accuracy and smoother movement. High resolution and clean signals give you the best results.

There are different ways to make sub-divisional error smaller in linear encoders. The best way uses electronic compensation. This method finds mistakes in the signals and fixes them. It works by looking for unwanted extra waves in the sine and cosine signals. The system then takes away these errors from the position reading. You do not have to change any parts. You get more accurate and steady results, even if things around the encoder change.

New research shows that a particle swarm optimization (PSO) model works really well. This model uses smart searching to find and fix problems like DC offset, amplitude error, quadrature error, and harmonic errors. It can fix both simple and complex extra wave problems. In tests, this method made both moving and still errors much smaller. Fourier analysis showed it also got rid of many bad extra waves. You get better real-time fixes and more accurate results. This way works better than old digital or software-only fixes.

Mechanical design helps too. Some encoders use special gratings together. These gratings make the system less likely to have mounting mistakes. If you use open-type optical encoders, mounting errors can cause big trouble. Special gratings help keep the phase more steady. You get fewer mounting errors and better measurements.

You can also use harmonic suppression. This method targets the extra waves in the signal. By removing these, you get cleaner sine and cosine signals. Cleaner signals mean less sub-divisional error and better detail.

Tip: Always check if your encoder has electronic compensation or special mechanical features. These options help you get the detail your job needs.

How you put in your encoder is very important. Good installation can really help lower sub-divisional error. You should put the feedback device close to where the work happens. This setup cuts down on errors like roll, pitch, and yaw. Use laser tools to line up everything just right. You can also use other tools for even better setup.

Keep the area around your encoder under control. Use shields and airflow to keep out dust and keep the temperature steady. Pads or air bladders help stop shaking. A steady temperature and little shaking help your encoder work its best.

Think about the materials you use. Do not mix materials that grow at different rates. For example, do not bolt low-CTE materials like Invar onto aluminum. This can make the scale bend or stretch, which causes more errors.

Keep your signals clean. Use EMI and RFI shields to block electrical noise. Check your wires and connections. Use tools like oscilloscopes to look at the signals. Make sure they are strong and balanced.

Calibration is very important. Measure small errors along the scale at different spots. Use rolling checks every 50 microns. This helps you find and fix tiny mistakes. Some companies use special machines to test the whole encoder at a steady temperature. These machines give you a pass or fail and a quality paper.

Note: Regular checks and tests help keep sub-divisional error low. Use good tools to watch signal strength and alignment. These tools show you Lissajous plots and other helpful graphs.

Here is a checklist for best installation:

Put the feedback device close to the work.

Use laser tools for setup.

Control temperature and shaking.

Use EMI/RFI shields.

Pick materials that grow the same way.

Test signals with good tools.

Calibrate often.

Use controls to keep temperature and humidity steady.

Test under load.

Make sure your encoder works with your control system.

Installation Step | Why It Matters | What You Gain |

|---|---|---|

Close feedback device | Cuts down on off-axis errors | Better accuracy |

Laser alignment | Makes sure setup is exact | Fewer mistakes |

Vibration isolation | Stops shaking and noise | Steady readings |

EMI/RFI shielding | Keeps signals clean | Trustworthy data |

Material selection | Stops thermal mismatch | Less bending |

Regular calibration | Finds and fixes small errors | Steady performance |

Lowering sub-divisional error is very important for high resolution and direct drive systems. These systems need very small errors to work well. When you make sub-divisional error smaller, you get better position readings at tiny scales. You also get the detail your encoder promises. New technologies like Verapath optical encoders can get sub-divisional error below 20nm RMS. This gives you the accuracy needed for tough jobs.

Remember: Every step you take to lower sub-divisional error helps you get the best detail and system performance.

You play a key role in keeping sub-divisional error low for the best accuracy in your motion systems.

To manage this, you can:

Use strong designs and materials that resist heat and shaking.

Apply smart control systems and sensors to watch for changes.

Test the whole system before using it.

Follow trusted standards for checking errors.

Keep learning and improving your process.

Staying alert to these steps helps you reach top performance in every project.

You usually see sub-divisional error when the sine and cosine signals from your encoder are not perfect. Problems like signal imbalance, phase shift, or distortion make this error repeat every signal period.

You can use a Lissajous pattern. Plot the sine signal on one axis and the cosine on the other. If you see a perfect circle, your signals are good. Any distortion means you have sub-divisional error.

No, it does not. Sub-divisional error repeats with each signal period. It stays small and does not add up as you move farther. You can trust that it will not grow over time.

Sub-divisional error limits how closely you can measure position or speed. If you want top accuracy in jobs like CNC machining or robotics, you need to keep this error as low as possible.