Views: 0 Author: Site Editor Publish Time: 2025-02-27 Origin: Site

In today's rapidly evolving technological landscape, encoders play a pivotal role in various industries, from industrial automation to robotics. Selecting the right encoder for your specific application ensures optimal performance, accuracy, and reliability. This comprehensive guide delves into the intricacies of encoders, including encoder resolution, single-turn encoders, and absolute encoders, providing you with the knowledge to make an informed decision.

An encoder is a device that converts motion into an electrical signal, enabling systems to monitor and control parameters such as position, speed, and direction. They are indispensable in applications requiring precise motion control and feedback.

Encoders are primarily categorized into two types:

Incremental Encoders: These encoders generate pulses in response to motion. The number of pulses corresponds to the distance traveled, while the pulse frequency indicates speed. However, they do not retain position information after power loss, necessitating a reference point upon restart.

Absolute Encoders: Unlike incremental encoders, absolute encoders provide a unique code for each position, retaining precise position information even after power interruptions. This feature eliminates the need for rehoming procedures upon system restart.

Encoder resolution refers to the smallest measurable increment of movement detected by the encoder. It is typically expressed in pulses per revolution (PPR) for incremental encoders or bits for absolute encoders. Higher resolution translates to finer measurement capabilities.

Incremental Encoders: Resolution is defined by the number of pulses generated per 360-degree rotation. For instance, a 1024 PPR encoder produces 1024 pulses in one full rotation, allowing position detection with an approximate accuracy of ±0.1 degrees.

Absolute Encoders: Resolution is denoted in bits, representing the number of unique positions per revolution. A 12-bit single-turn absolute encoder offers 4096 distinct positions, equating to a resolution of 0.088 degrees per position.

Selecting the appropriate encoder resolution is crucial. Insufficient resolution may lead to inadequate feedback, compromising system performance. Conversely, excessively high resolution can result in unnecessary complexity and cost.

Absolute encoders are further divided into:

Single-Turn Absolute Encoders: These encoders determine the position within one 360-degree rotation. After completing a full turn, the position data resets. They are ideal for applications where position tracking within a single revolution suffices, such as measuring the angle of a pivoting arm.

Multi-Turn Absolute Encoders: These encoders track both the position within a single turn and the number of complete revolutions. They are essential in applications requiring continuous position tracking over multiple turns, like in robotics or CNC machinery.

The choice between single-turn and multi-turn depends on the application's specific requirements for position tracking.

Choosing the right encoder involves evaluating several key factors:

Application Requirements: Determine the specific needs of your application, including the type of motion (linear or rotary), required precision, and environmental conditions.

Resolution: Assess the necessary encoder resolution based on the precision required. Higher resolution provides finer control but may increase system complexity and cost.

Environmental Conditions: Consider factors such as temperature, humidity, exposure to contaminants, and mechanical vibrations. Some encoders are designed to withstand harsh environments, while others are suited for controlled settings.

Output Signal Type: Ensure compatibility between the encoder's output signal (e.g., analog, digital, PWM) and your system's input requirements.

Mounting and Size Constraints: Evaluate the physical dimensions and mounting options to ensure the encoder fits within the available space and integrates seamlessly with existing components.

Budget: Balance the features and performance with cost considerations to select an encoder that meets your requirements without exceeding budget constraints.

Encoders are utilized across a wide range of industries and applications:

Industrial Automation: Providing feedback for motor control systems, ensuring precise positioning and speed regulation.

Robotics: Enabling accurate movement and positioning of robotic arms and mobile platforms.

Aerospace: Assisting in the control and monitoring of aircraft components and systems.

Medical Equipment: Ensuring precise operation of medical devices such as imaging systems and surgical robots.

Renewable Energy: Monitoring the position of wind turbine blades and solar panels to optimize energy capture.

In conclusion, selecting the best encoder for your needs involves a thorough understanding of your application's requirements, the different types of encoders available, and the specific features each type offers. By considering factors such as encoder resolution, environmental conditions, and application-specific demands, you can make an informed decision that enhances your system's performance and reliability.

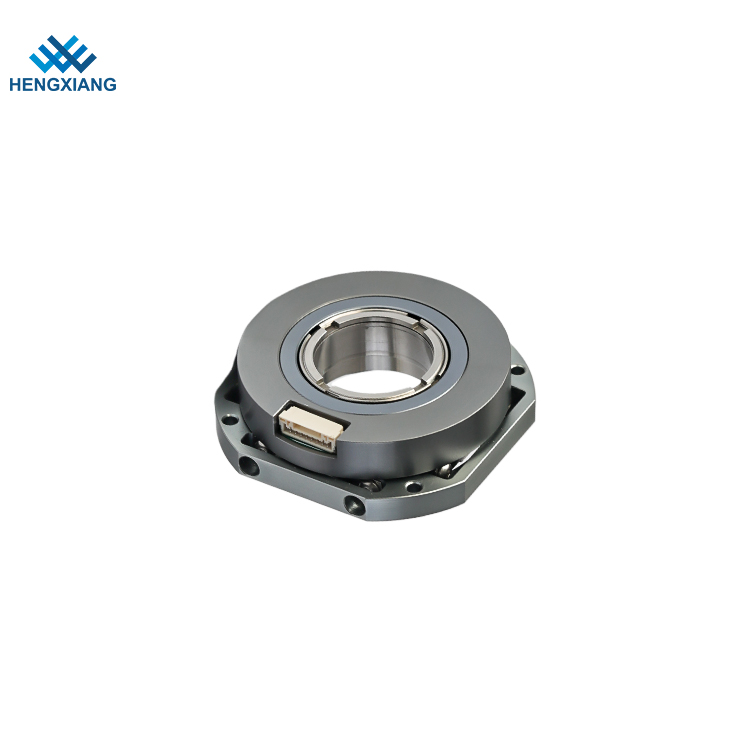

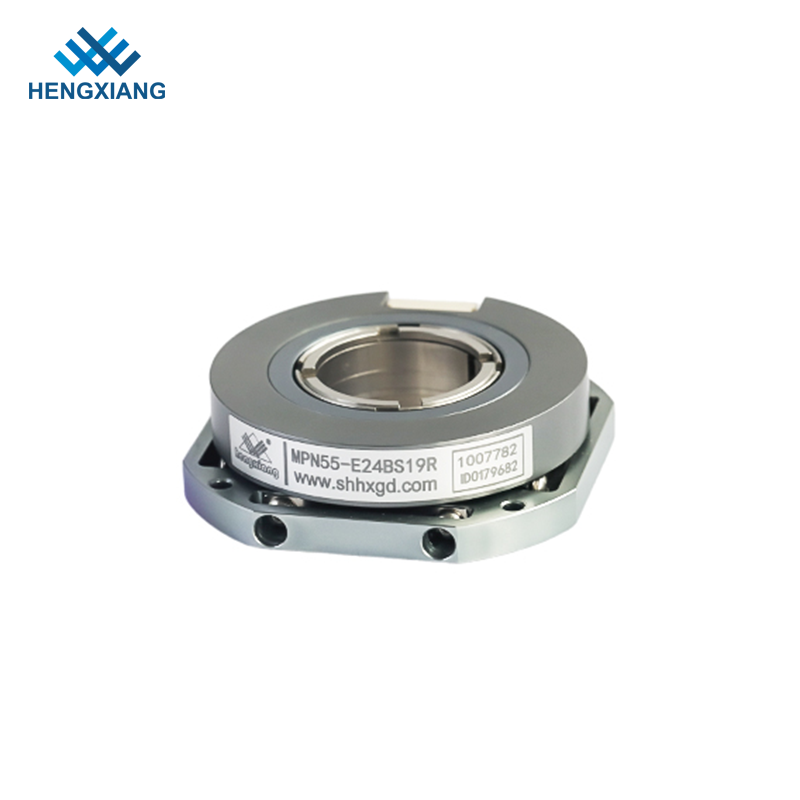

When selecting an encoder, partnering with a reliable manufacturer ensures long-term success. Shanghai Hengxiang Optical Electronics Co., Ltd. brings over 23 years of experience in high-precision sensor R&D and encoder manufacturing, making us a trusted choice for businesses worldwide.

Quality Assurance: Our products have passed authoritative certifications, including CE-ATC, ISO, and QMS, through rigorous third-party testing.

Leading Technology: We continually innovate with a professional design team, holding 3 invention patents and 38 utility model patents.

Customization & Flexibility: We provide tailor-made encoders for diverse machinery, meeting varying precision requirements with proven technical expertise.

One-Stop Service: From design and production to shipping and distribution, we offer full-cycle corporate services to streamline your experience.

Efficient Support: With fast response times and optimized resource management, we help you save time and maximize system efficiency.

At Shanghai Hengxiang Optical Electronics Co., Ltd., we are committed to delivering superior service, exceptional quality, and competitive pricing. Whether you need a high-resolution absolute encoder for industrial automation or a single-turn encoder for precise motion control, we have the expertise to provide the perfect solution for your application.

Q1: What is the difference between incremental and absolute encoders?

A1: Incremental encoders generate pulses corresponding to movement and require a reference point upon startup, while absolute encoders provide a unique position value, retaining position information even after power loss.

Q2: How do I determine the appropriate encoder resolution for my application?

A2: Evaluate the smallest movement increment your application needs to detect. For example, to measure a 3-degree movement, an encoder with at least 120 PPR (360°/3°) is required.

Q3: When should I choose a single-turn absolute encoder over a multi-turn encoder?

A3: Opt for a single-turn encoder if position tracking within one revolution suffices. For applications requiring position tracking over multiple revolutions, a multi-turn encoder is more suitable.

Q4: Can encoders operate in harsh environments?

A4: Yes, many encoders are designed to withstand extreme temperatures, humidity, dust, and vibrations. It's essential to select an encoder rated for the specific environmental conditions of your application.

Q5: What output signal types are available for encoders?

A5: Encoders offer various output signals, including analog (e.g., voltage variations), digital (e.g., TTL, HTL), and pulse-width modulation (PWM). Ensure the chosen encoder's output is compatible with your system's input.

In conclusion, selecting the best encoder for your needs involves a thorough understanding of your application's requirements, the different types of encoders available, and the specific features each type offers. By considering factors such as encoder resolution, environmental conditions, and application-specific demands, you can make an informed decision that enhances your system's performance and reliability.